- One of the key benefits of sourcing Tio2 from factory price suppliers is the cost savings. These suppliers often have direct relationships with Tio2 manufacturers, allowing them to negotiate lower prices for bulk purchases. This cost advantage is then passed on to manufacturers, helping them reduce their overall production expenses.

Titanium dioxide (TiO2) is used in a variety of personal care products, including sunscreens, pressed powders, and loose powders, as a UV filter or whitening agent. In lotions and creams (dermal exposure), it is not a risk for adverse health effects. However, when titanium dioxide is inhalable—as it may be when in powder form—it is considered a possible carcinogen by the International Agency for Research on Cancer.Titanium dioxide nanoparticles do not appear to confer any unique health hazards.

In order to evaluate the penetration of the nanoparticles, eight adult male Wistar rats (3 months old) were used for the in vivo experiments. The protocol was approved by the local University Committee for animal testing and is in accordance with the Canadian Council on Animal Care (CICUAL-RD-2021–892-E-UNC-DEC#FCQ).

After drying, the sample is weighed precisely, and through stoichiometric calculations, the amount of titanium dioxide in the original sample can be determined

. The resulting calculation helps determine the gravimetric percentage of titanium dioxide present, providing manufacturers with critical information for quality control.

barium zinc sulphate supplier. Reliability, purity standards, consistent supply chains, and competitive pricing are all factors that must be considered when choosing a supplier. A reputable supplier should also provide comprehensive technical support and be capable of meeting stringent quality control measures to ensure that the barium zinc sulfate supplied meets the specific needs of each industrial process.

barium zinc sulphate supplier. Reliability, purity standards, consistent supply chains, and competitive pricing are all factors that must be considered when choosing a supplier. A reputable supplier should also provide comprehensive technical support and be capable of meeting stringent quality control measures to ensure that the barium zinc sulfate supplied meets the specific needs of each industrial process. These processes can significantly reduce the amount of energy and chemicals required, while also generating fewer byproducts These processes can significantly reduce the amount of energy and chemicals required, while also generating fewer byproducts

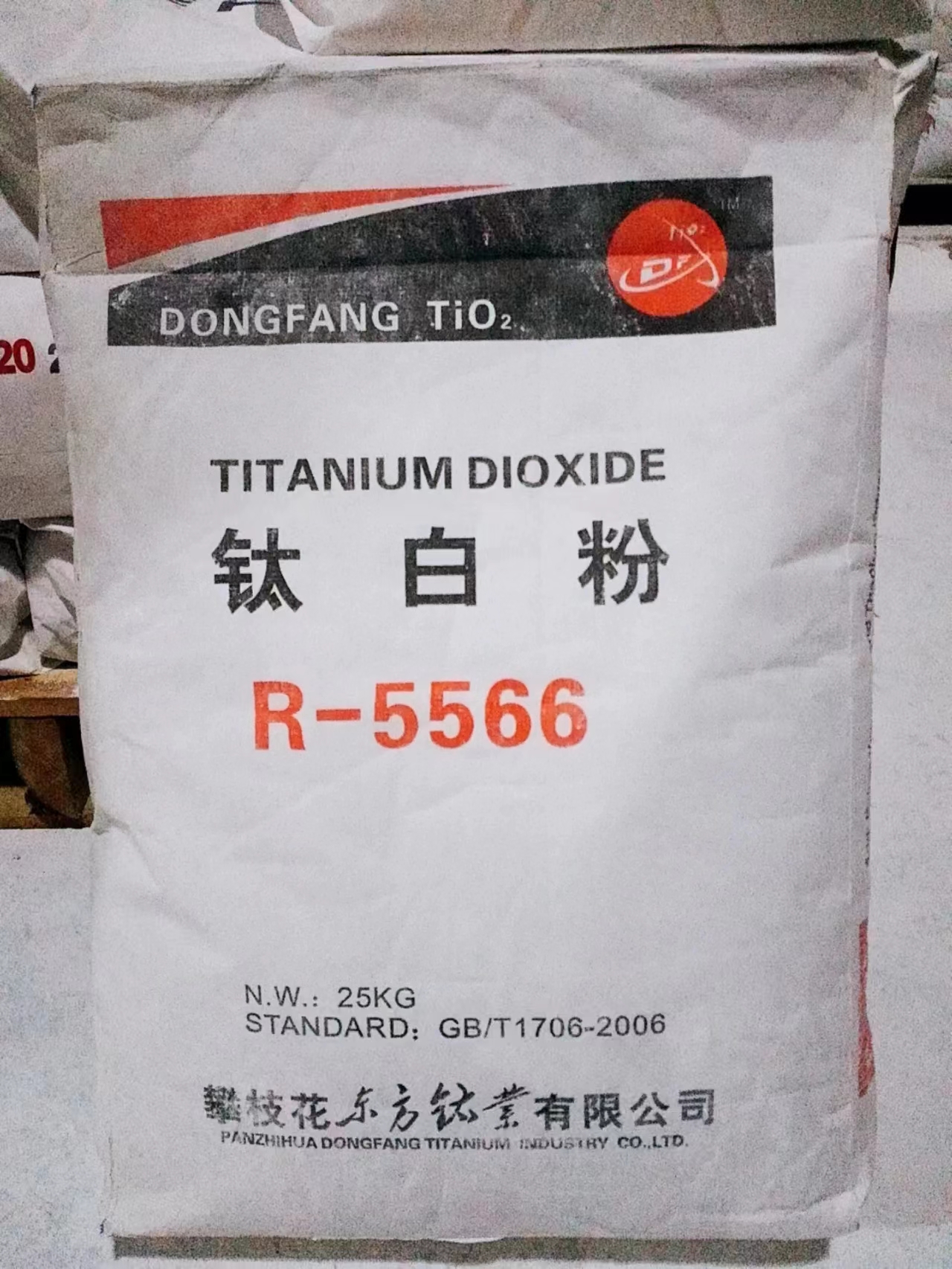

These processes can significantly reduce the amount of energy and chemicals required, while also generating fewer byproducts These processes can significantly reduce the amount of energy and chemicals required, while also generating fewer byproducts r 5566 titanium dioxide factories.

r 5566 titanium dioxide factories.better

cl 77891 titanium dioxide supplier. Our commitment to excellence extends beyond simply providing the raw material; we also offer technical support and guidance to help our customers achieve optimal results in their applications.

cl 77891 titanium dioxide supplier. Our commitment to excellence extends beyond simply providing the raw material; we also offer technical support and guidance to help our customers achieve optimal results in their applications.White powder

Their global reach and efficient logistics ensure timely delivery, making them a preferred partner for many businesses Their global reach and efficient logistics ensure timely delivery, making them a preferred partner for many businesses

Their global reach and efficient logistics ensure timely delivery, making them a preferred partner for many businesses Their global reach and efficient logistics ensure timely delivery, making them a preferred partner for many businesses dioxide titanium b101 anatase powder supplier.

dioxide titanium b101 anatase powder supplier.Technical Specifications:(Standard:Q/SNBJ1-2012)